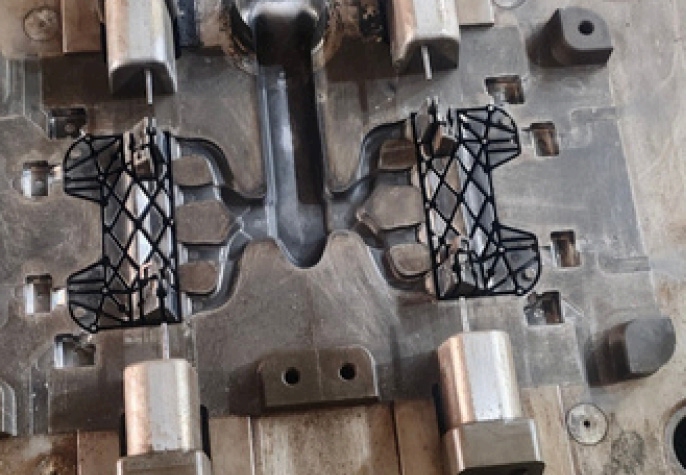

Mold

Our mold department has eight professional mold product designers and product stylists who can conduct comprehensive analyses of mold structures and product structures.

Raw materials

We use qualified aluminum, zinc and magnesium ingots from certified suppliers. All incoming materials undergo composition verification, batch recording and appearance inspection before entering production.

Smelting

Our smelting area uses centralized melting furnaces and insulation furnaces to maintain stable alloy temperature and purity. Metal is melted, filtered and tested to ensure it meets die casting process requirements before entering production.

Die casting

The die casting workshop has 17 die casting machines, including one 1250T and one 800T hot chamber die casting machine, which basically cover the die casting product requirements of the home appliance industry.

Processing

Equipped with state-of-the-art processing equipment both domestically and internationally, we specialize in the production of large, precision, and complex die-cast products.

Warehouse

Strictly enforce the 5S management system, post flowcharts, safety warnings, labels, etc., to ensure that standards are visible.

Contact Our Metal Manufacturing Team

Discuss your OEM project with our metal manufacturing experts — we provide custom die casting, machining, and fabrication solutions tailored to your design.